When Were Nonwoven Fabrics First Made?

Early humans discovered the concept of nonwoven textiles by felting wool, matting together animal fibers, and creating simple fabrics without weaving or knitting. Over time, nonwoven techniques evolved and adapted to various cultures and needs.One of the oldest forms of nonwoven fabric is felt, which dates back over 6,000 years. Nomadic tribes in Asia developed the art of felting wool into warm, durable clothing and shelter materials. This process involved applying heat, moisture, and friction to mat together the fibers, creating a dense, nonwoven textile.

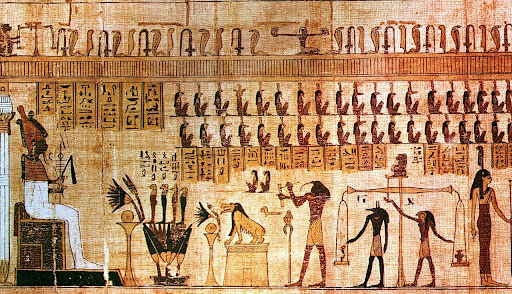

The ancient Egyptians used nonwoven techniques to create papyrus, a nonwoven writing surface made from the pith of the papyrus plant. This versatile material was also used to craft mats and baskets. The Maya civilization in Mesoamerica produced bark cloth, another form of nonwoven fabric. They extracted fibers from the inner bark of certain trees, which they would then flatten and stretch into thin, nonwoven textiles.

The Evolution of Modern Nonwoven Fabrics

The Industrial Revolution in the 18th and 19th centuries revolutionized the textile industry and introduced significant advancements in nonwoven fabric production.The spunlaid nonwoven process was developed in the 20th century. Synthetic fibers such as nylon and polyester became popular for creating nonwoven fabrics. The spunlaid method involved extruding molten polymer through tiny holes, forming continuous filaments that could be laid down and bonded into a nonwoven structure.

Wetlaid and drylaid nonwoven methods became popular in the mid-20th century and led to the diversification of nonwoven fabric applications. Wetlaid nonwovens involve suspending fibers in a water-based solution, which is then filtered to create a web of fibers. Mechanical, thermal, or chemical methods are used to create drylaid nonwovens, which bond fibers together without water.

Nonwovens Evolve to Serve a Wide Range of Industries

Today, nonwoven fabrics are successfully being used in a diverse range of applications. They are used for filtration, personal care products, commercial fabrics, and medical applications. The ability to customize nonwovens for specific needs made them a versatile material for countless products. Some of the many types of nonwoven fabric fiber and customization options available today include:As the emphasis on sustainability and eco-friendliness in product development grows, nonwovens will continue to play an essential role in creating environmentally conscious consumer goods. We can expect to see the development of bio-based nonwoven materials, which are derived from renewable resources and biodegradable. Moreover, innovations in nanotechnology and smart textiles will enable nonwoven fabrics to possess advanced properties, such as self-cleaning surfaces, enhanced filtration, and even embedded electronics.

Your Dependable and Capable Source for Nonwovens

As a leading domestic nonwoven fabric manufacturer since 2008, WPT Nonwovens is dedicated to producing quality products and providing uncompromised service. Our goals in meeting these objectives include:- Providing the Highest Quality Nonwovens and Comprehensive Services

- Developing Key Supplier Relationships for a Reliable Supply Chain

- Leading the Nonwovens Industry in Zero Waste Manufacturing Strategies

- Designing Innovative, Environmentally Responsible, and Sustainable Nonwovens

We look forward to meeting your needs as your trusted nonwoven fabric manufacturer and supplier. Contact us to discuss your project.