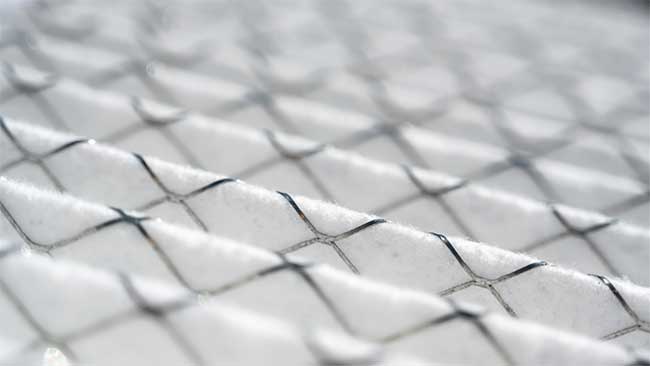

Bicomponent fibers are comprised of two individual components distributed over the full length of the finished fiber. The components can be from the same or entirely different polymer types, and each might possess distinct physical or chemical properties.

Bicomponent fibers are comprised of two individual components distributed over the full length of the finished fiber. The components can be from the same or entirely different polymer types, and each might possess distinct physical or chemical properties.

In creating two polymers to create a single fiber, the unique properties of each are imparted on the bicomponent fiber. This results in a bicomponent fiber with specific characteristics that can be applied in variety of applications.

Concentric sheath/core is a configuration used to melt fibers with a low melting point polymer sheath around a core with a high melting point. The concentric sheath/core process is also applied to produce fibers with a quality, higher-price core with a weaker external polymer outer layer.

Our bicomponent nonwoven fabric is available with a variety of fabric treatment options such as:

- Anti-microbial/anti-bacterial

- Anti-static

- Heat sealability

- Hydrophilic

- And more

Why buy bicomponent nonwoven fabric from WPT Nonwoven?

Some nonwoven suppliers are only interested in filling large volume orders. WPT is positioned to serve not only high volume needs, but we are also happy to fill small niche orders. Other advantages we offer include:

- Ability to provide a sample within 30 days

- Production and shipment of your order within four to six weeks

- Extensive experience in developing nonwoven polyester fabric

- Unsurpassed customer service

- A fully capable manufacturing facility located in Beaver Dam, Kentucky

Ready to discuss your bicomponent nonwoven needs? Contact us today!